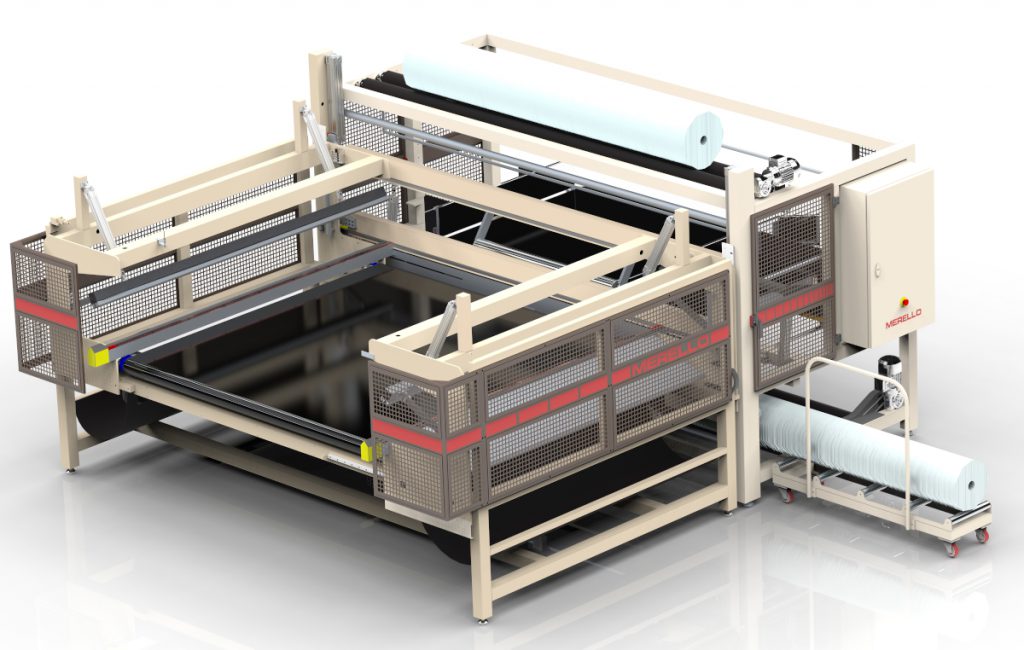

Mattresses packing machine

ME-103

ME-103

The ME-103 offers affordable pricing, performance and compact design combined with great value.

Features

- The bag is made from plastic rolls (PE), thickness from 50 to 200 microns.

- Automatic adjustment of the width and thickness of the mattress. Manual height adjustment.

- Configurable machine: from the minimum cost and size, up to all automation and speed options.

- Mattress measures: from 170x70x10 to 225x225x50.

- Cold welding,: highest quality, minimum consumption, ready to use from the first minute.

- Plastic cuts made by cold blade: free of maintenance, smoke or odors.

- Transistorized PLC control and touch screen that reports the status of the machine.

- Variable speed drive in all engines to extend their life.

Optional equipment

- Double seal, more safety against breakings.

- Automatic adjustment of the mattress height.

- Assistance for light mattresses and toppers. By motorized rollers (puller) it helps the mattress to pass through the plastic.

- Lateral press. Detects the thickness of the mattress and applies the programmed pressure to achieve a better adjustment of the bag.

- Reinforcing coil: motor rolls to place additional plastic coils.

- Stacker: Packed mattresses are placed directly on a trolley for transport to the warehouse. The price includes 2 trolleys.

- Crane lift for plastic coils: It can raise and bring to the work position coils up to 250 kg. It includes a pneumatic system to move both coils to the working position.

- Conveyor belts available: input, output, corner tables(90)…