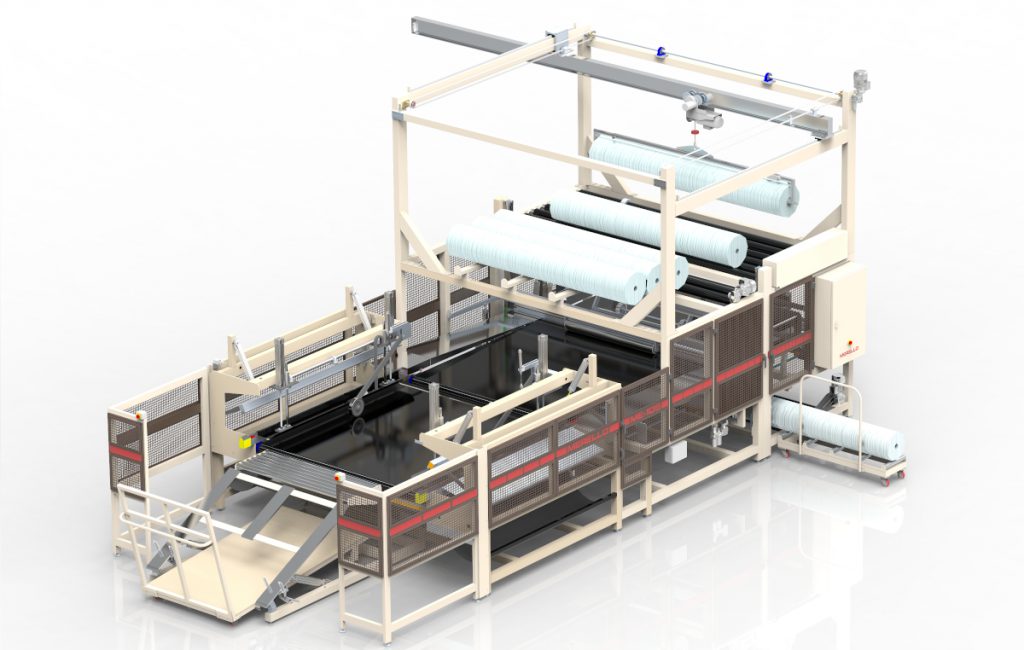

The fastest wrapper machine

ME-105

ME-105

The ME-105 machine pockets extra-fast mattresses and beds of any size with a perfect fit.

Features

- The bag is made from plastic rolls (PE), thickness from 50 to 200 microns.

- Automatic adjustment of the width, height and thickness of the mattress.

- High productivity: independent width adjustment in all phases of the machine allows it to work simultaneously with three mattresses and reach speeds of up to 5 cycles per minute.

- Mattress measures: from 170x70x10 to 225x2250x50.

- Cold welding,: highest quality, minimum consumption, ready to use from the first minute.

- Lateral press. Detects the thickness of the mattress and applies the programmed pressure for further tightening of the bag.

- Plastic cuts made by cold blade: free of maintenance, smoke or odors.

- Reinforcing coil: motorized rollers to place additional plastic rolls.

- Transistorized PLC control and touch screen that reports the status of the machine.

- Variable speed drive in all engines to extend their life.

- The machine can store 4 + 4 coils in work position.

Optional equipment

- Double seal, more safety against breakings.

- Automatic adjustment of the mattress height.

- Assistance for light mattresses and toppers. By motorized rollers (puller) it helps the mattress to pass through the plastic.

- Lateral press. Detects the thickness of the mattress and applies the programmed pressure to achieve a better adjustment of the bag.

- Reinforcing coil: motor rolls to place additional plastic coils.

- Stacker: Packed mattresses are placed directly on a trolley for transport to the warehouse. The price includes 2 trolleys.

- Crane lift for plastic coils: It can raise and bring to the work position coils up to 250 kg. It includes a pneumatic system to move both coils to the working position.

- Conveyor belts available: input, output, corner tables (90)…