Mattress Packaging

Machine

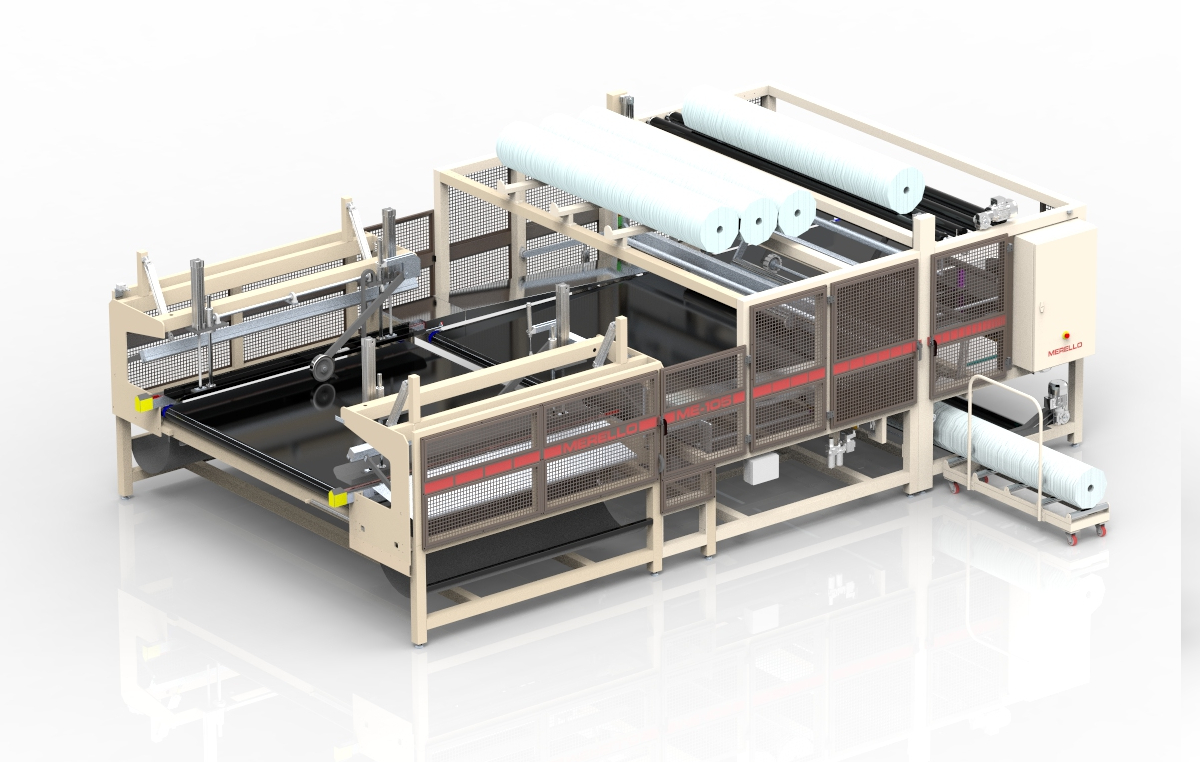

ME-104

Highlight Features

Main benefits

High output with consistent bag fit

Designed for fast mattress bagging up to 4 pieces per minute, while maintaining a tight and uniform finish thanks to automatic product adjustment and controlled tightening.

Perfect tightening with lateral press + impulse sealing

The lateral press detects mattress thickness and applies the programmed pressure to tighten the bag. Combined with impulse sealing (cold welding), it delivers high-quality seals, low consumption and no warm-up time.

Built for long runs and quick roll management

Maintenance-friendly design with cold blade trimming (no fumes/odours) and VFD drives to extend motor life. Plus, it can keep 4+4 film rolls in working position, ideal for continuous production and fast changeovers.

Textile packaging: mattresses and toppers

High-speed roll-fed PE mattress packaging with automatic 3D adjustment

The machine forms the bag from PE film rolls (50–200 microns) and automatically adjusts width, height and thickness to match the mattress dimensions, delivering a clean and consistent result for handling, transport and storage.

Its packaging quality is reinforced by impulse sealing (cold welding)—ready from the first minute—and a lateral press system that tightens the bag according to the programmed pressure. With modular options and conveyor integration, it fits both standalone operation and in-line industrial workflows.

Media Gallery

ME-104 Mattress packaging machine

For higher protection and bag stability, the machine can be equipped with double sealing. For lightweight products such as toppers, motorized puller rollers can assist feeding through the film. The lateral press function and reinforcing film rolls can also be configured to achieve a tighter, better-fitted bag depending on product and line needs.

Packed mattresses can be transferred directly to a trolley using an automatic stacker (includes 2 trolleys). For easier film handling, a film roll lifting crane is available to load and bring heavy rolls (up to 250 kg) into working position, including a pneumatic system to position both rolls. The system can be integrated with infeed/outfeed conveyors and 90° corner tables for complete line layouts.

comparison chart

Technical features

These specifications are subject to change according to customer requirements

if you require further information