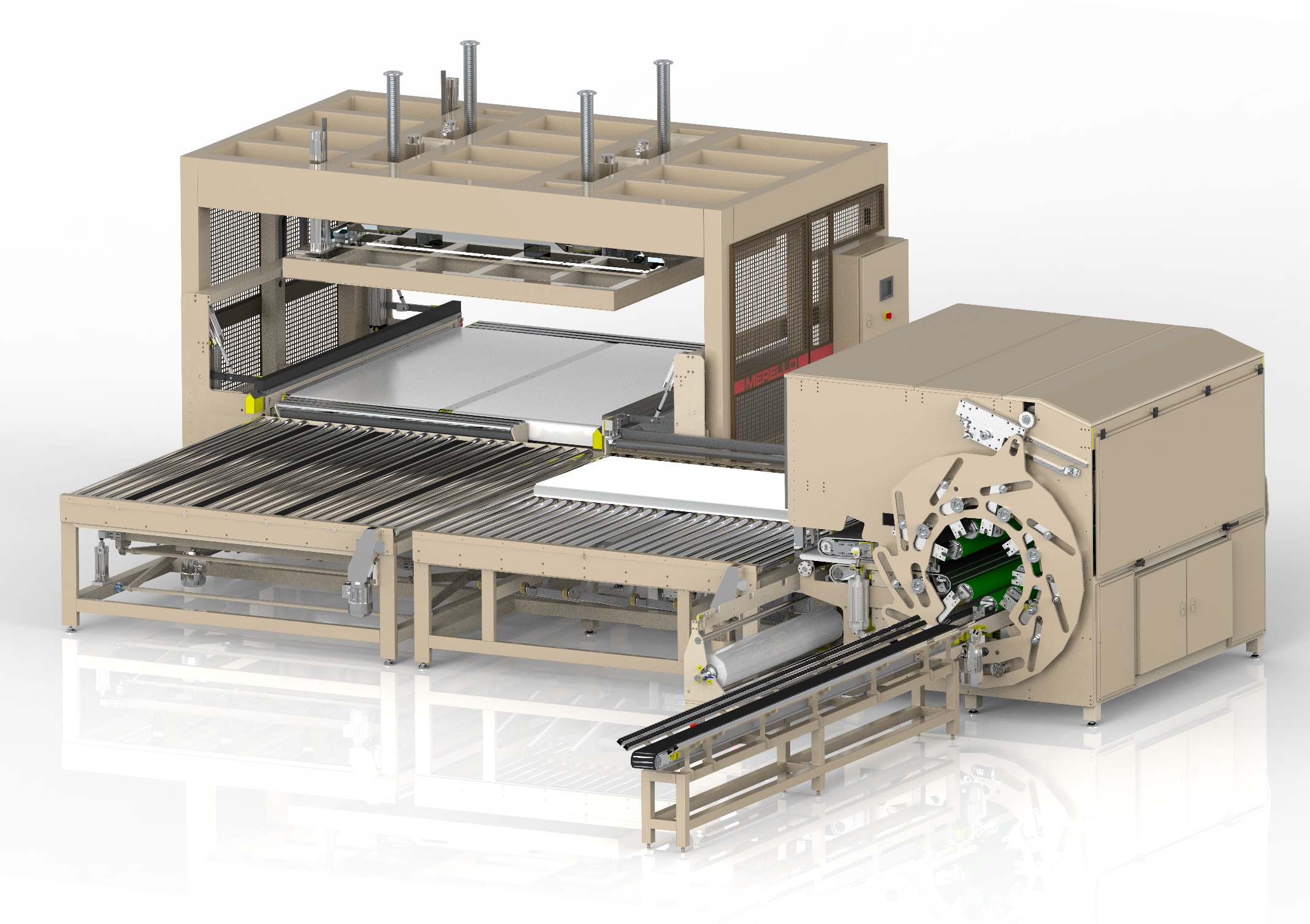

Mattress Roller

And Press Machine

ME-406

Highlight Features

Main benefits

Precision roll packing with programmable final diameter

The ME-406 rolls mattresses and toppers with outstanding consistency thanks to its continuous-diameter roller cage, which adapts during the process to keep rolling effort stable. The final roll diameter can be set per product (approx. Ø25–Ø50 cm).

Fully automatic cycle for high productivity

Runs a complete automatic cycle: pressing, rolling, packing and ejection, reaching up to 4 pieces per minute (depending on product and configuration).

Industrial reliability with clean finishing

Includes VFD drives to extend motor life, PLC + touchscreen HMI, smooth/fast module movements, and a knife cut for a clean, neat finish. Designed for safe operation (CE compliant).

Industrial mattress pressing & roll packing

Automatic roll packer with continuous-diameter cage and torque-controlled rolling

This industrial machine is designed for pressing and roll packing mattresses and toppers, delivering a very consistent result thanks to a continuous diameter cage that follows the real mattress volume throughout the cycle.

Its architecture uses motorized rollers with independent variable speed control (no traction chains), ensuring stable rolling dynamics across the full diameter range. The process is fully automated and can be integrated into a packaging line to increase throughput and improve handling efficiency.

Media Gallery

ME-406 Mattress Roller and Press

The ME-406 adapts to different mattress formats while maintaining a uniform roll and a programmable final diameter. For large mattresses, it can be complemented with folding/turning solutions to reduce pack size and optimize logistics (depending on configuration).

Optional equipment includes bagging units (roll-only or roll + bag), 90° corner table for feeding direction, and automatic film change (2 positions) to reduce downtime. The system can also be configured for integration with other Merello mattress packaging machines.

comparison chart

Technical features

These specifications are subject to change according to customer requirements

if you require further information