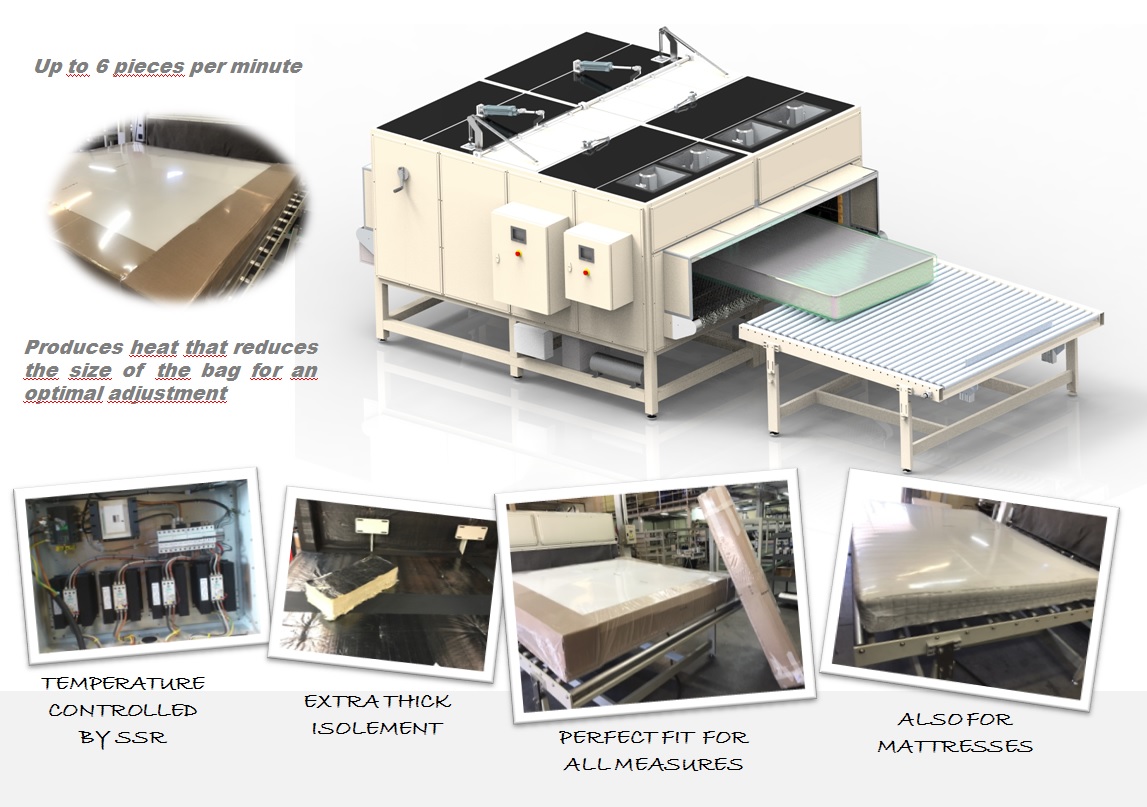

Shrinking tunnel

Machine

ME-125

Highlight Features

Main benefits

Purpose-built for beds and mattresses (no extra energy required)

Designed specifically for this product category: the tunnel dimensions match bed/mattress formats, helping achieve a uniform shrink finish without oversized heating and unnecessary energy use.

Fast, stable temperature control (PLC + SSR)

Controlled by PLC and SSR, enabling analog-like temperature regulation with very fast reactions (1-second control cycle) for repeatable, consistent shrink quality.

High thermal efficiency and industrial safety

Features maximum thermal insulation (8 cm mineral wool) to reduce heat losses, selectable installed power, and enhanced safety functions (conveyor monitoring, fan monitoring, electrical consumption monitoring and a top-opening system for fast cooling).

Industrial shrink wrapping for mattresses

Forced-air shrink tunnel for beds and mattresses with precision temperature control

This tunnel is designed to shrink PE-bagged beds and mattresses, achieving a tight film finish and a more compact, stable pack for handling, transport and storage. Its design uses forced hot-air flow to reduce shrink time and improve uniformity across the product surface.

The system is controlled by a PLC with touchscreen HMI and power regulation via SSR, ensuring stable temperature and fast response to changes. It also includes multi-point temperature monitoring for even heat distribution, plus adjustable air deflectors to adapt airflow to different product thicknesses.

Media Gallery

ME-125 Shrinking Tunnel

To minimize energy consumption, the tunnel includes high-efficiency thermal insulation (8 cm mineral wool) and selectable installed power (20 to 90 kW), with an approximate 10-minute warm-up time. Forced-air flow, temperature monitoring and adjustable deflectors help deliver a consistent shrink finish across different mattress heights.

Safety is designed for continuous industrial operation: monitoring of conveyor movement, electrical current/consumption, and fans, plus a top-opening system that releases heat quickly when stopped or in emergency (fast cooling), and a dual thermal safety circuit. Motors include variable frequency drives (VFDs) to extend service life.

comparison chart

Technical features

These specifications are subject to change according to customer requirements

if you require further information