Mattress Packaging

Machine

ME-105

Highlight Features

Main benefits

Maximum productivity for mixed sizes

Thanks to automatic size detection across the three modules and independent motion, it can process multiple mattresses simultaneously and reach up to 5 pieces per minute (more than 4 pcs/min with mixed sizes).

Tight bagging and secure sealing from the first minute

The impulse sealing system (cold seal bar / “cold welding”) delivers reliable seals across a wide film thickness range, with minimum consumption and no warm-up time. The result is a tight, well-finished pack.

Clean finishing and industrial reliability

It features cold blade trimming for a clean cut (no fumes or odours), a PLC with touchscreen HMI, and drives with inverters/servo for fast, smooth movements. The machine is designed for safe operation (CE compliant).

spring and foam mattresses

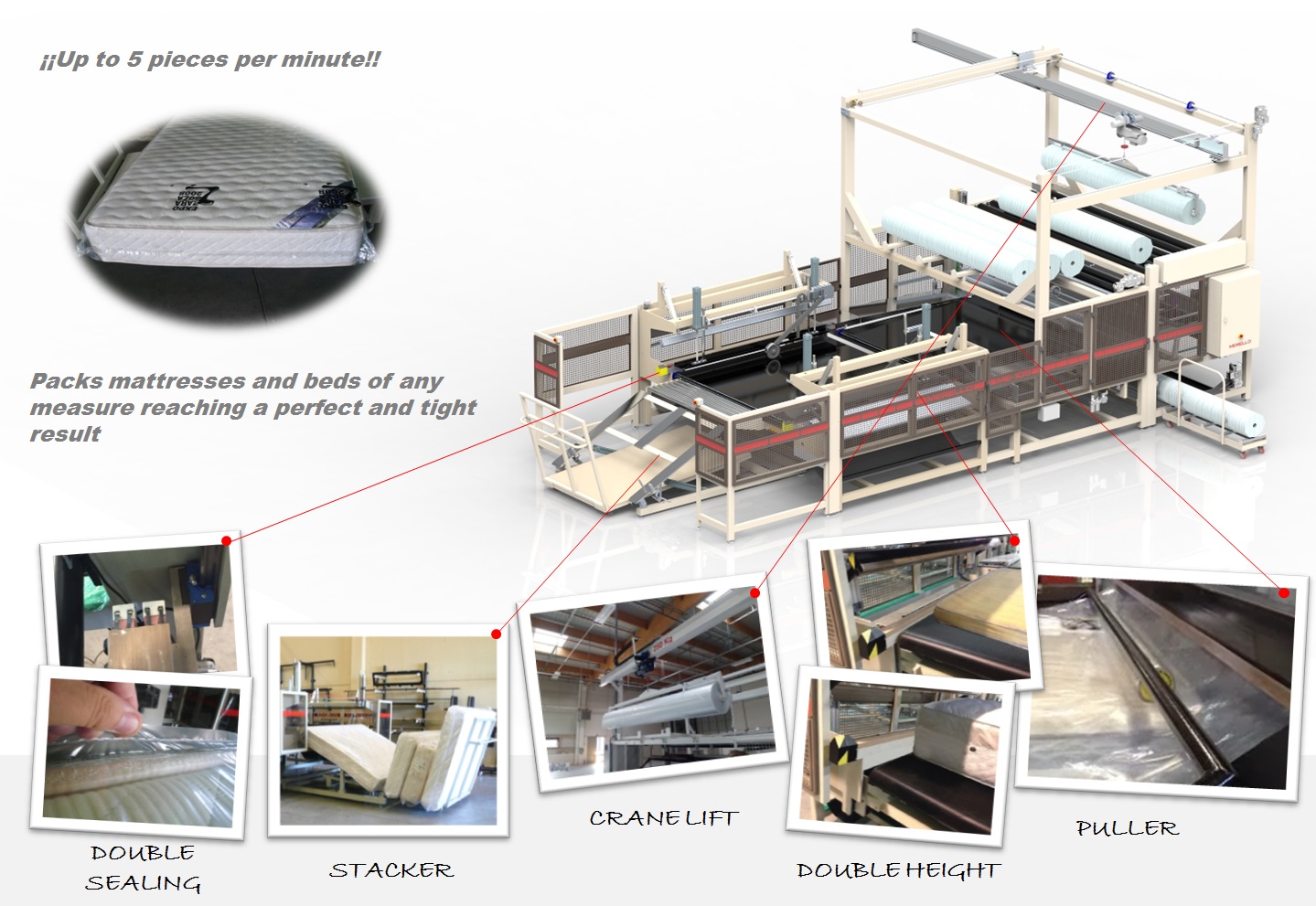

High-speed roll-fed PE mattress bagging with automatic 3D adjustment

The machine bags spring and foam mattresses using polyethylene (PE) film from rolls, delivering a tight finish and consistent sealing. It works with 50–200 micron film thickness and automatically adjusts width, height and thickness to match different product dimensions.

To ensure consistent pack quality, it integrates an automatic compression device (thickness detection + programmed pressure) and impulse sealing, ready from the first minute. Its modular design with independent movements enables high-speed operation and maintains an efficient flow even when running mixed mattress sizes.

Media Gallery

ME-105 Mattress packaging machine

For additional security, the machine can be equipped with double sealing. To optimize film consumption when running high/low mattresses, a double height system is available. For lightweight products such as toppers, motorized puller rollers can be added to assist feeding through the film.

For automated output, an automatic stacker is available to fill transport trolleys, and a film roll lifting crane can be added for easier roll handling. The machine can also be integrated with infeed/outfeed conveyors and 90° corner tables, depending on the line layout.

comparison chart

Technical features

These specifications are subject to change according to customer requirements

if you require further information