VACUUM PACKAGING

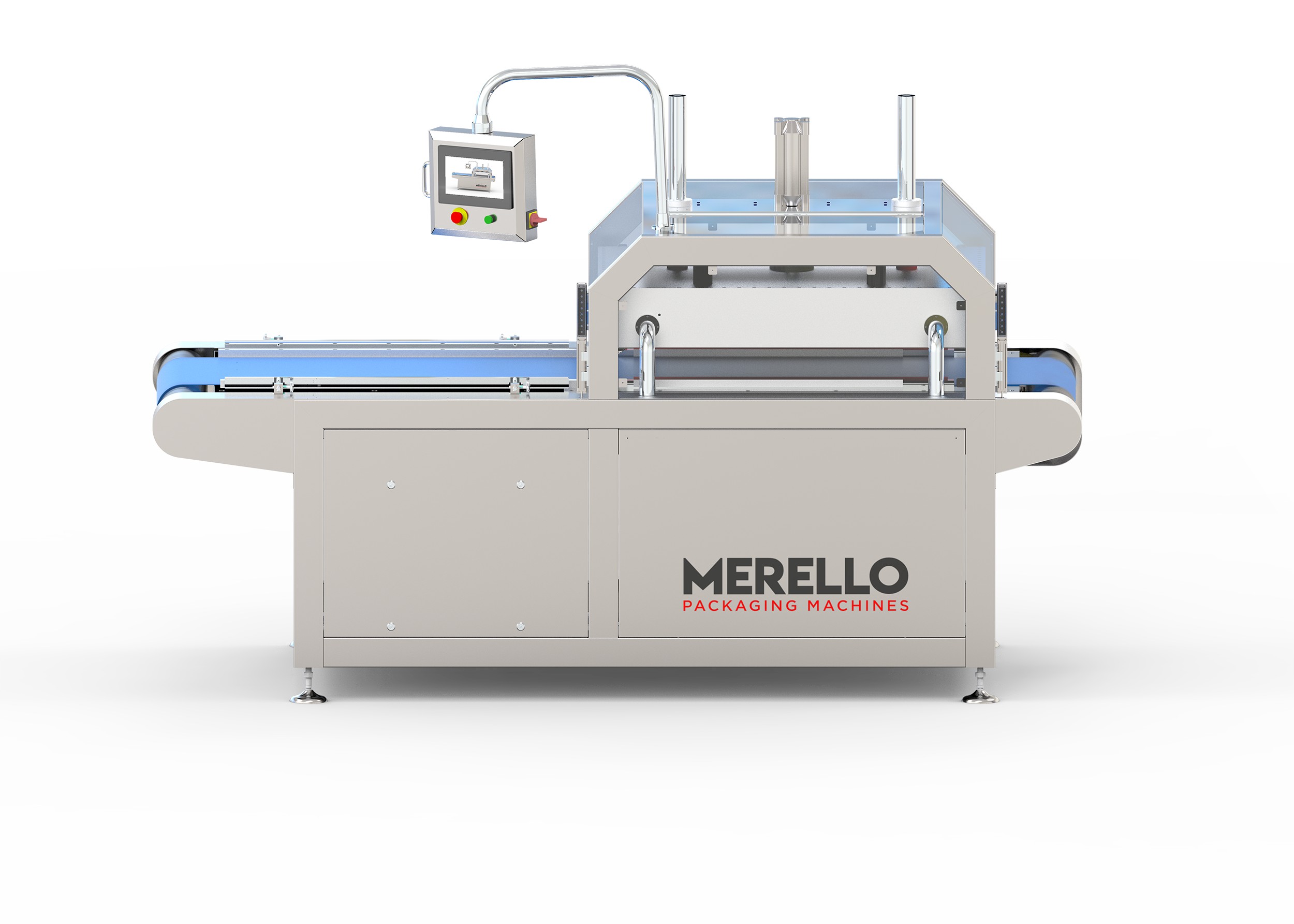

ME-901

SEALS BAGS UNDER HIGH VACUUM ENSURING PRODUCT PRESERVATION

Description

The ME-901 seals the bags after applying vacuum, extracting the air to extend the shelf life of the packaged products.

The sealing system is carried out by means of a nichrome plate located on the side bands of the vacuum chamber. Optionally, it can be equipped with a side cutting guillotine.

It can also be equipped with a vacuum cleaner for cutting or pre-cutting the excess.

The servomotorized infeed conveyor allows both integration into an automatic packaging line and manual preparation of the next batch.

Sanitizable construction made entirely of stainless steel. Easy accessibility to the internal components of the machine for cleaning.

With a productivity of 2.5 cycles per minute, this machine is suitable for packaging any food product.

Technical Data

Dimensions: 1460 x 2158 x 1056 mm

Weight: 1500 Kg

Noise: 15 dB (A)

Power consumption: 2 KW

Voltage: 220 V (L+N)

Pneumatic consumption: 500 liters/cycle at 6 bar

Connection: Ethernet bus

Production: 2.5 cycles / min

Sealing height: up to 70 mm

Feeds: 800 x 1600 mm

(Varies according to customer specifications)